The Challenge

Keeping track of operations functions within manufacturing facilities, such as supply chain and manufacturing key performance indicators (KPIs), help monitor the facility’s productivity and performance. Monitoring these issues are key to seeing the overall health and effectiveness of current efforts, while also indicating areas to improve on.

A manufacturing facility found tracking their KPIs from several facilities to be a time-consuming and inefficient chore. Vital KPIs were spread across multiple platforms, making it difficult for the client to compare and track KPIs. Not only did the client need insight into specific root causes of inefficiencies within facilities, but they also needed this information in an easily accessible location. Evalueserve developed a tracking system that aided the client in spotting inefficiencies across multiple facilities. They also made sure to include insights from broad comparisons and measurements of all the client’s facilities.

Our Solution

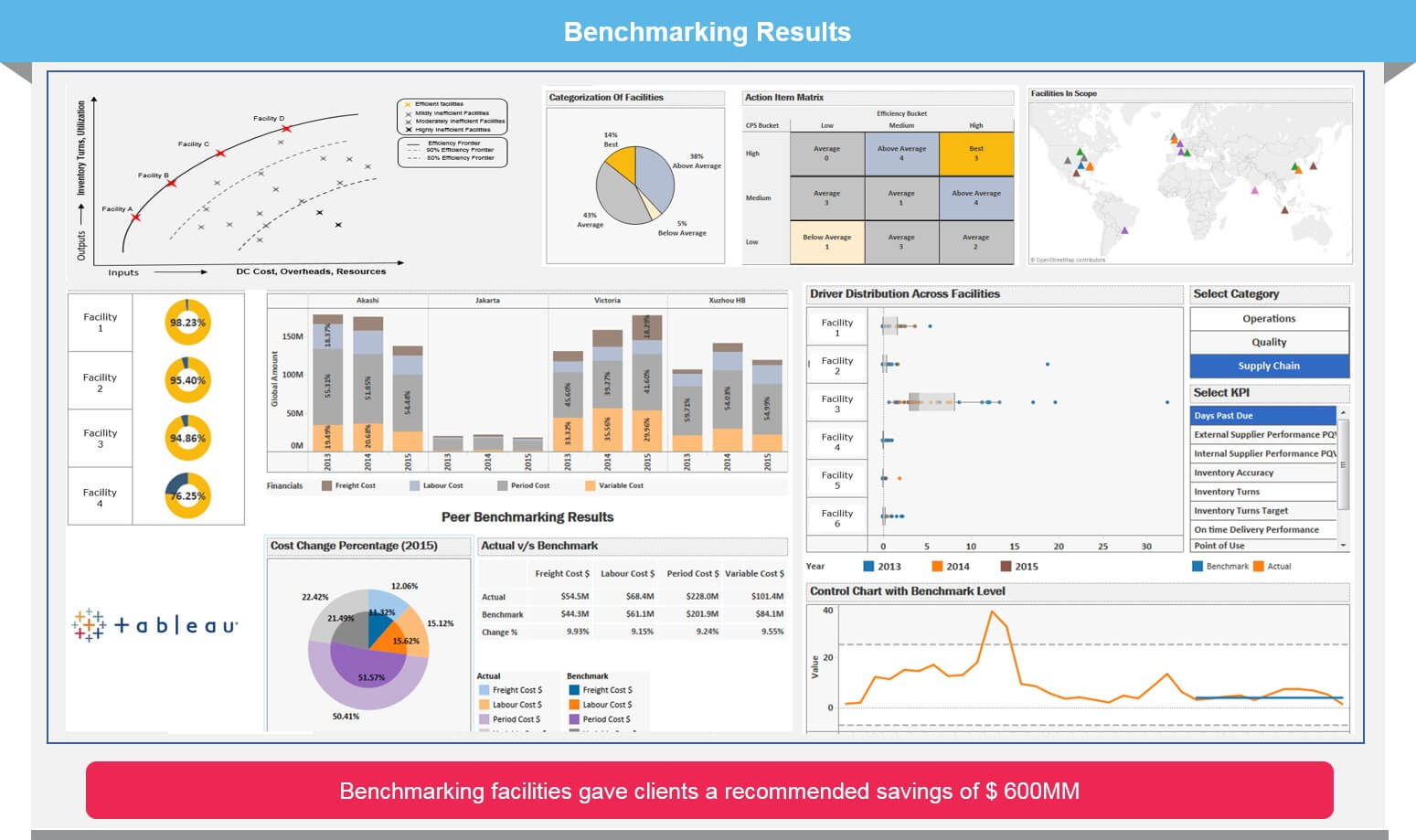

In order to track hundreds of crucial KPIs, Evalueserve developed a data visualization intelligence tool that featured key information from all of the client’s manufacturing facilities. This information provided insight into each facility’s operational efficiency level. The Evalueserve team used a combination of multivariate regression and operations research-based algorithms. These algorithms worked to identify significant drivers of operational efficiencies and inefficiencies.

Due to the wide distribution of manufacturing facilities across a variety of regions, the client had difficulties bringing all of the information into one place. Without being able to look at all the information, the client couldn’t prioritize efforts and calculate an accurate return on investment (RoI). The Evalueserve team’s solution enabled the client to prioritize specific facilities that experienced low scores on efficiency and financial performance tests by using a benchmarking platform. Having this key information in one central location streamlined the KPI and facility monitoring system, helping the client quickly gain insights into their facilities. Emphasis was placed on using visuals like graphs, charts and maps as informative vehicles in which insights could be drawn at a glance.

Business Impact

As a result of using the new manufacturing facility intelligence tool, the client can prioritize improvement efforts and calculate RoI, resulting in expected savings of $20M across all facilities. This shows how the client hugely benefitted from having hundreds of KPIs condensed into one location. Now the client can look at ways to fix root causes of operation inefficiencies in specific locations without sacrificing time or effort.

Expected savings of $20M

Operations team across manufacturing locations can access the intelligence tool to monitor progress and quickly respond to problems, resulting in a high RoI

Focused approach to issues

Hundreds of condensed KPIs found in one location can help the client make improvements to their manufacturing facilities.

Talk to One of Our Experts

Get in touch today to find out about how Evalueserve can help you improve your processes, making you better, faster and more efficient.