Growing demand for Rare Earth Materials has encouraged supply chain leaders to be more vigilant

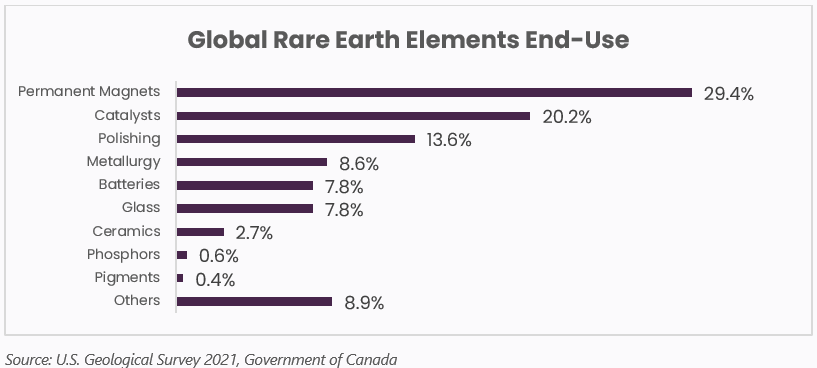

Rare-earth Elements (REE) are not actually rare but are found across the globe in Asia, the Americas, Africa, and Australia. They are referred to as rare only because of the limitations in mining and refining processes. These elements are used in defense applications (electronic displays, guidance systems, lasers, radar, and sonar systems) and high-tech consumer products (cellular telephones, computer hard drives, electric and hybrid vehicles, etc.). In the past, the demand for REE was driven by their unique application in magnets used in color televisions. At present, this demand has grown exponentially as REEs are now used in multiple products and applications such as chargeable batteries, EVs, and clean energy generation.

Source: U.S. Geological Survey 2021, Government of Canada

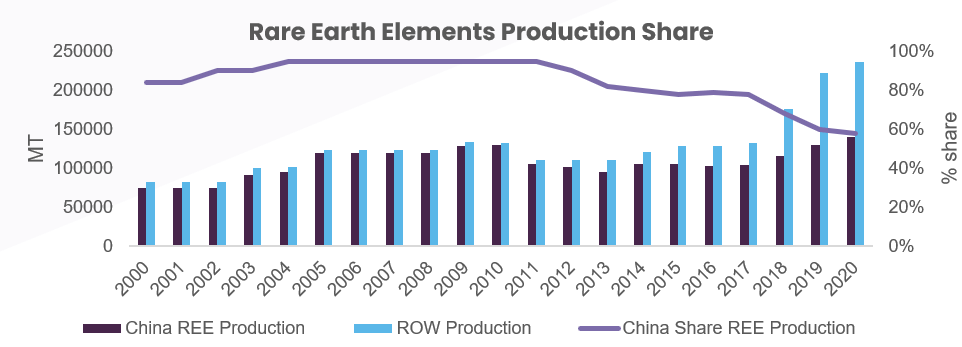

The US was the first country to start REE mining. It started in the 1960s and ruled the global market until the 1990s when China took over the market. China’s dominance has been supported by its end-to-end mining and processing capabilities, lower wages, and relaxed environmental laws. Over the last few years, western companies have been exploring partnerships to build alternate supply chains with other nations to reduce China’s dominance.

China’s REE Dominance in the Global Market

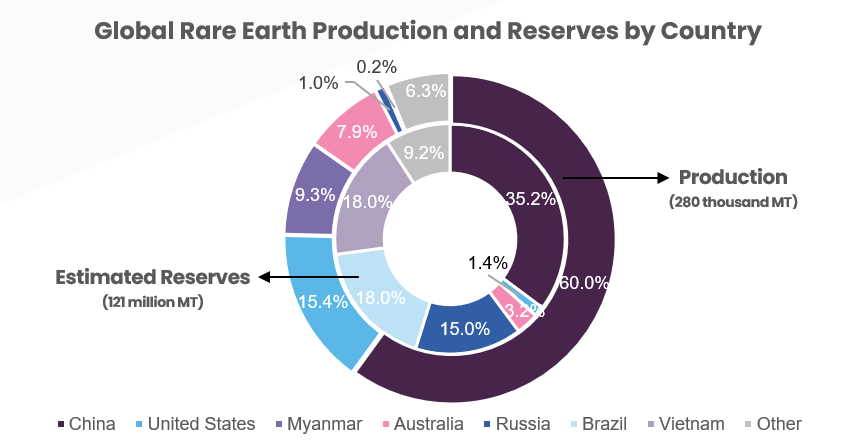

China is the leading REE producer and the only country with end-to-end capabilities (mining to processing). It has a global mineral output share of ~60% and a refining capacity of ~85%. It also accounts for ~35% of the world’s REE reserves equivalent to rare earth oxides (REO). Around 80% of REE ores and concentrates are processed in China. Therefore, it has become the leading REE importer of intermediate rare earth materials for processing and controls the supply chain of downstream and mid-stream suppliers.

Source: U.S. Geological Survey, 2021

In terms of REE reserves, China (35%) is followed by Brazil and Vietnam, each accounting for ~18% of the global share. Though the US, Australia, and Russia mine significant amounts of REE, they lack processing capabilities.

REE demand stems primarily from Europe, the US, Japan, China, and South Korea – locations with a significant amount of high-tech goods and component manufacturing. In the next five years, the demand for REE is expected to be 2-8 times more than the current supply.

Sustainable procurement and supply of processed REE is a major issue for players in the global market. Apart from this, over-dependence on China and high REE prices seem to be pertinent problems for the market.

Why REE prices have always been so volatile?

Over the years, China has strategized its decisions to be able to reach its current market position. China’s easy access to raw materials and long-term plans have enabled it to subsidize prices by creating economies of scale. While other western countries became conscious about their environment, they sent their mined ore and concentrates to China. With China having the required expertise and filing more than 80% (~25,911) of the new international patents related to rare earth technology as of 2020, penetrating the market is difficult for international competitors.

In 2010, China limited its REE exports to Japan over a territory dispute. Due to the country’s dominance in the market, REE prices surged by almost 100 times, which encouraged capable market players to invest in the market and make profits. China’s actions skyrocketed the price of neodymium by ~750% and dysprosium by 2000%. These prices were normalized in 2015 when the World Trade Organization declared the country’s REE export quotas unlawful.

China, the largest REE producer, processor, and exporter in the world, has limited its export quotas, which often does not allow other countries to stock REE for future use. As a result, REE demand is mostly high in the market. The price of REE in the local markets in China is much lower than that in the global markets.

There are only a few REE processing facilities outside China – one in Malaysia (feedstock comes from Australia) and another in Estonia (~70% of its feedstock comes from Russia). The end products from these facilities are distributed to downstream industry suppliers in Europe and the US.

The US has been importing >80% of its REE requirements from China. It also imports 12% of its REE requirements from plants in Malaysia, Estonia, and Australia. The country is trying to reduce its dependence on China and focus on building its assets. Recently, it reopened its Mountain Pass mine in California (shut down in 2002 due to unfavorable prices and environmental and mining regulations). However, it is witnessing delays in setting up REE processing operations, which leaves it with no option but to rely on foreign suppliers.

Source: U.S. Geological Survey, “Rare Earths,” 2000–2020.

Though the share of China in total REE production has reduced over the last few years, given that RoW has initiated their mine production, still China invisibly controls the market being the largest consumer of rare earth elements.

Rising Defense Expenditures to Keep the Demand High for REE in 2023

The Russia-Ukraine conflict has compelled other countries to focus on enhancing their defense capabilities. For instance, Germany, in February 2022, allocated EUR100 billion (~2% of its GDP) to defense spending. With more countries ramping up their defense capabilities, the demand for REE will surge. However, given the global supply chain constraints, there will be a major gap in supply and demand. These developments are bound to keep the prices high for REE in the near future unless demand weakens due to recession fears. The Increasing demand for REE would require robust measures to build a sustainable and consistent supply chain.

Building a Resilient Global REE Supply Chain – Initiatives by the West

Although many countries are engaging in R&D activities, and exploring new trade partnerships, environmental risks, regulatory costs, and low-density deposits are still the major factors that hamper the implementation of projects. Countries are announcing pilot projects to domestically process REE and are reusing and recycling REE to create a closed-loop ecosystem to reduce their dependence on China.

Starting in 2021, companies in the west have entered into partnerships. For instance,

- In January 2021, Rio Tinto and the Quebec government invested USD6 million to set up a new environment-friendly project for Scandium, which is an extremely high-priced REE in North America.

- In the same month, Lynas Rare Earths signed an agreement with the US government to construct an REE separation facility with a production capacity of 5,000 tons per annum in Texas, US. The project is part of Lynas’ 2025 plan, and the facility will receive material from Lynas’ cracking and leaching plant in Kalgoorlie, Western Australia.

- In February 2021, the Biden administration launched a 100-day review of supply chains including REE. The government has approved funds of ~USD2 trillion to develop domestic processing plants; conduct feasibility studies for new mining projects and processing technologies; and understand the potential risks to the US economy.

- Australian Strategic Materials, an integrated ‘mine to metals’ company, plans to develop an REE mine at Dubbo, New South Wales, and a refinery in South Korea.

- In December 2021, Beijing announced the merger of three state-owned REE mining companies – Aluminum Corporation of China, China Minmetals, and the Ganzhou Rare Earth Group. The merged entity controls ~70% of the raw material and downstream industries. It is creating an integrated ecosystem and making it economically unviable for other big players to enter and compete in the market.

- In November 2022, the Swedish state-owned iron ore mining company LKAB announced to become the main investor in and owner of REEtec, a Norwegian firm, REEtec. REEtec has been developing technology to separate rare earths from impurities and refine them into high-quality, high-purity materials, known as rare earth oxides, for use in products like electric vehicle motors and wind turbines. REEtec will source its raw material, known as rare earth carbonate, from Canada’s Northwest Territories. LKAB, Europe’s largest iron ore producer, will also supply REEtec with raw materials from 2027.

Currently, the global REE market is dominated by a few countries as the processes and technologies are integrated. The unseen macroeconomic and geopolitical factors (COVID-19, Ukraine-Russia war) have had an adverse impact on buyers, thereby disrupting the global supply chain. With the resurgence of Covid cases globally, the risk for REE supply chain disruption persists. Hence, buyers need a long-term solution to mitigate supply shocks. A comprehensive intelligence partner can offer timely, accurate, and bespoke business solutions and market insights to drive decision-making and simultaneously help in addressing the challenges in the industry supply chain.